Drilling 101 The Basics

What is different about the Marcellus Shale?

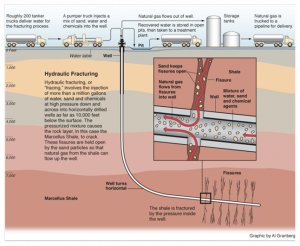

There has been gas drilling in the US for over 100 years in conventional gas plays. But a new drilling process, called “high-volume hydraulic fracturing,” has made the huge natural gas reserve in the Marcellus Shale recoverable.

Extent of Formation

Unlike other gas formations, the Marcellus is vast and continuous. Although it varies in depth and thickness, it underlies the entire southern half of the state, as well as occurs beneath the surface of much of Ohio, West Virginia and New York, even extending into small areas of Maryland, Kentucky, Tennessee and Virginia.1

Hydraulic Fracturing

Hydraulic Fracturing

Unlike in conventional gas reserves, the gas in the Marcellus is trapped and dispersed throughout the shale in tiny pores, and must be released in a process called hydraulic fracturing, or fracking. In each fracking, 2–9 million gallons of water mixed with sand and chemicals are forced through the well into the formation at high pressure to fracture, or crack, the shale. Roughly half of the fracking fluid remains in the ground. The rest of it—1,000,000 to 4,000,000 gallons—comes out of the well and is considered industrial waste that requires disposal. Each well may be fracked several times during its productive life.2

For more detailed information on drilling, please view this video produced by the American Petroleum Institute: Natural Gas Horizontal Shale Drilling

Well Pad Information

Marcellus wells are long-lived, remaining active up to 40 years. When hydrofracked and drilled horizontally, Marcellus wells require large, industrial pad sites. Depending on how many well heads it contains, a pad will range from 5–15 acres.

StatOilHydro—a large Norwegian multinational co-developing the Marcellus Shale—has developed schematics conveying six horizontal wells being drilled from one well pad, with four well pads in a small area. In addition to drilling several well pads from one site, the industry also tends to work in a grid fashion that best maximizes the production of gas from the well.

Anthony Ingraffea, PhD, is a professor at Cornell and a world renowned expert on hydraulic fracturing. In these videos he explains the process and its potential environmental impacts to a group of interested citizens.

Besides drilling several well pads from one site, the industry also tends to work in a grid fashion that best maximizes the production of gas from the well. This process is better explained in the referenced video featuring Dr. Ingraffea from Cornell University.

We encourage you to take the time to at least view Part 1 of the video in this section Dr Ingraffea presents a concise, organized, educated summary of the facts about gas drilling that we all need to understand.

Part 1 (10 min) Overview of cumulative impacts of drilling

Part 2 (10 min) Discusses well spacing, development , flowback

Water Water Everywhere

Water Everywhere

Fracking requires large quantities of fresh water. In fact, the process will require many billions of gallons of water over the next 15 years. This water will be withdrawn from lakes, rivers, streams, wetlands, ponds, and wells. Because the water becomes contaminated, it may never be returned to the watershed and disposal of this contaminated water becomes challenging.3

Fracking Fluids

Most of the recent advances in fluid technology for shale gas recovery are owned by Halliburton. The gas industry describes fracking fluids as being “like soap and oil.” Halliburton classifies the fracking fluids as proprietary. Samples from well blowouts and fluids pits in Colorado, Wyoming and New Mexico found fluids to contain diesel fuel and more than 200 different kinds of chemicals, over 95% of which have adverse side effects including brain damage, birth defects and cancer.4

Fluids Disposal

The produced water from the Marcellus Shale is toxic waste. In addition to the added chemicals, the water picks up hydrocarbons, heavy metals like arsenic, and radioactivity from the shale.5 Billions of gallons of waste water will be produced in our area alone and will need to be trucked to a final disposal site. The most common method of disposal in the US is Deep Well Injection Disposal, where the waste is forced underground at high pressure into dry gas wells6, but due to geology in PA, this is not an option—this is of particular concern being that some waste products contain radioactive materials that require special handling and processing.

Sources

(1) Pennsylvania Geology, The Marcellus Shale-An Old “New” Gas Reservoir in Pennsylvania, Vol. 38, NO.1, 2008

(2) http://www.propublica.org/special/hydraulic-fracturing

(3) Calculations based on water withdrawal rates by companies operating in Pennsylvania. Susquehanna River Basin Commission,

Bucknell University, September 11, 2008 http://www.srbc.net/programs/projreviewmarcellus.htm

(4) Analysis of Chemicals Used in Natural Gas Production: Colorado, Theo Colborn, PhD, February 6, 2008